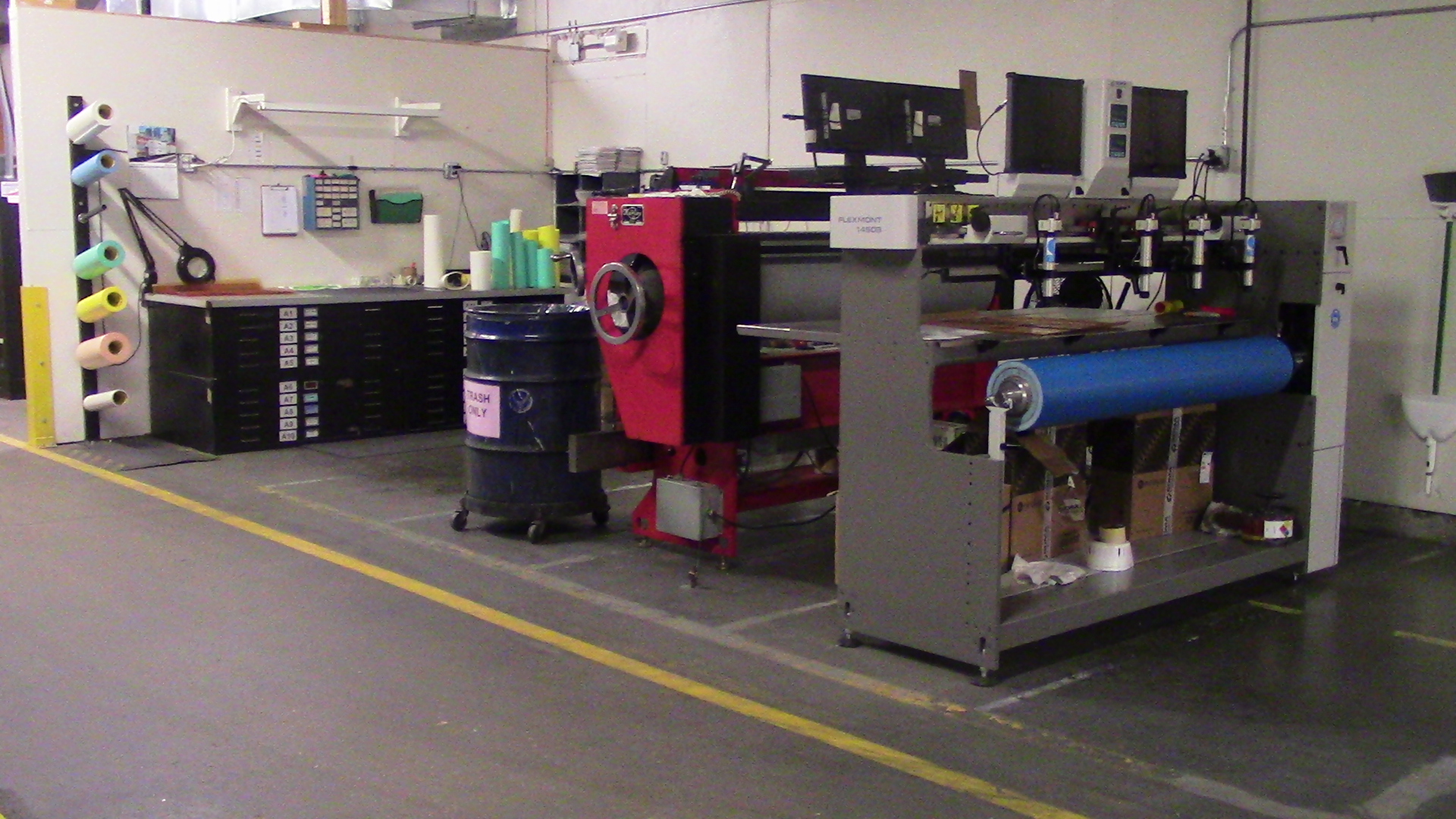

Printing

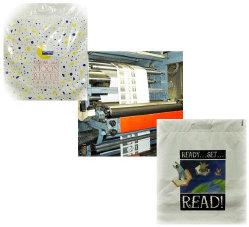

We use the latest in flexographic printing technology to print your design on custom blown polyethylene film.

We are capable of printing 1 to 8 colors in either line or process printed designs, surface printed film, reverse printed film, surface printed bags, or reverse printed bags.

We do not create or design the artwork for printing. We only accept artwork and designs direct from the customer.